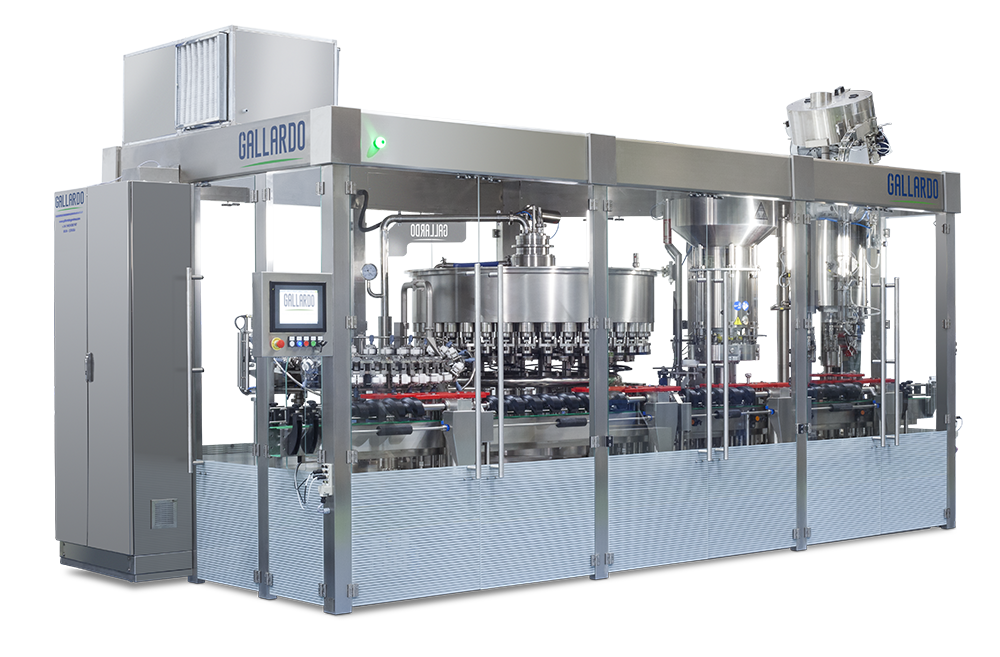

Ciders Conventional gravity bottling machine

- Closed, pressurised cabin - laminar flow

- Filling tap with diaphragm

- Non-vacuum gravity filling system - does not generate foam

- Automatic product levelling system

- AUTOCLEAN automatic cleaning system

- Auto-programmed CIP unit

- Advanced diagnostic capabilities with INDUSTRY 4.0

APPLICABLE TECHNOLOGIES

PACKAGING MATERIALS

- Glass

TYPES OF PACKAGING

- Bottles

VOLUME OF PACKAGING

0,75 L

TYPES OF STOPPER/CAP/LID

- Cork

PERFORMANCE BOTTLES/HOUR (B/H)

Up to 12,000 B/H

FILLING/VALVE PROCESSES

- Vacuum-free fill-to-level filler

- Filling tap with diaphragm

Models

MONOBLOC

FILLING

CAPPING

Filling

Our bottling machines make the filling process more efficient and accurate

Capping

Single capping (capping machine or corking machine)

TRIBLOC

RINSING-BLOWING

FILLING

CAPPING

RINSING-BLOWING

Cleaning can be done with water or air.

Filling

Our bottling machines make the filling process more efficient and accurate

Capping

Single capping (capping machine or corking machine)

CUATRIBLOC

RINSING - BLOWING

FILLING

CAPPING (DOUBLE CAPPING TURRET)

Rinsing - Blowing

Cleaning can be done with water or air.

Filling

Our bottling machines make the filling process more efficient and accurate

Capping (double capping turret)

Using a double capping turret (capping and corking).

All our bottling machines of Ciders

Conventional gravity bottling machine